rot is by far the most extensive project I've ever worked on. This was my capstone project at parsons school of design, however the work for this project really started in 2022 when i began taking shoe making courses and working under a shoe maker in NYC. So i learned a lot about the way shoes are made and how to make them far before i began exploring sustainable solutions for footwear. But i always knew my main goal for a shoe project would be a sustainable shoe concept, so for my final project at school i explored how to make a biodegradable shoe!

In the beginning the backbone of this project was really to ensure that even if this shoe ended up in the hand of the worst possible consumer, the shoe would still cause as little harm to the environment at the end of its life. Today many sustainable products are only effective if the consumer carry out specific steps once the product is dead. If the consumer doesn't do this then the product can be just as bad as anything else. With this shoe I wanted to make sure that even if someone threw these shoes in the trash and they ended up in a landfill somewhere that they'd eventually fully degrade and not leach any toxins or chemicals into the environment while degrading.

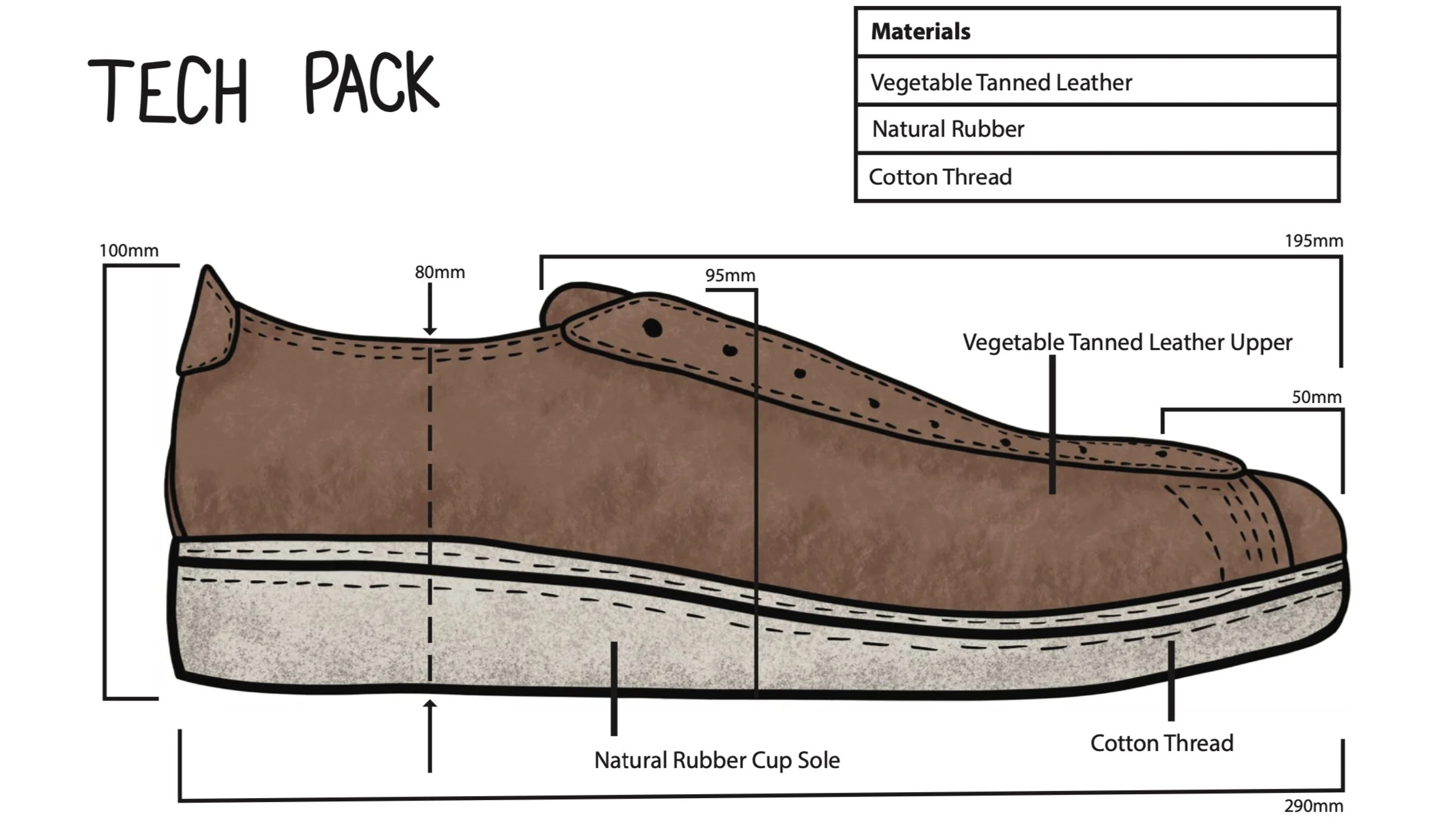

So through this process I found a way to make a shoe using only three materials vegetable tanned leather, cotton, and natural rubber. No adhesives were used at all in the making of this shoe! This is because shoe making adhesives usually contain toxic chemicals. So essentially the shoe was lasted (the process of forming a shoe around the shoe form), stitched, and attached to the sole without adhesives. This might not seem very tricky but adhesives are literally used in each of these shoe making steps, wether that's holding pieces in place that will eventually be stitched (upper) or relying only on the adhesive to hold pieces together (sole).

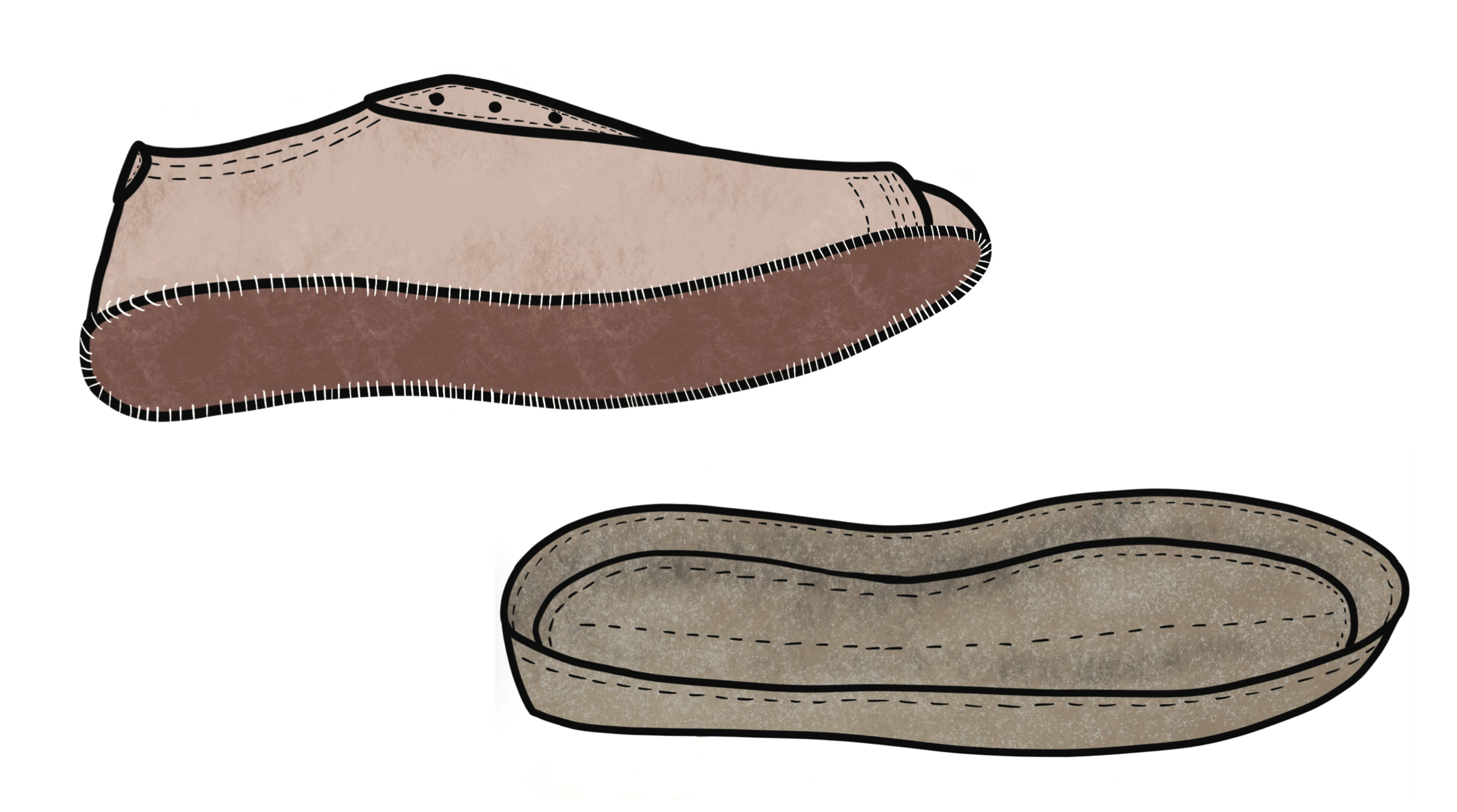

How did i do this? Well through simple pattern making (a simple pattern allowed me to stitch the upper together without worrying about using glue to hold the pieces in place). Then there is something magical in shoe making called a welt! A welt is the process of stitching an upper to an insole, then stitching that whole piece to the outsole! In modern welted shoe glue is also used but before common adhesives shoes were made without glue using just the welt. So I lasted the shoe, then stitched on the insole, then stitched it to the outsole. then boom an incredibly simple shoe made using only three materials!

However making the shoe wasn't the only important part to this project. I now needed to wear the shoes! and wear them I did! And so did my roommates because luckily we all have the same shoe size! So for six weeks we all wore these shoes on and off to put them through a wear test. And they held up! This wear test resulted in no failures in the construction and the shoe showed wear like any other shoe would! I even still wear the shoes now!

Lastly I wanted to present a more manufacturable model for this shoe. I came up with a concept that would use a strobal stitched insole (commonly used in sneaker making) to attach the upper to the insole, then a cup sole made of natural rubber would be attached to this upper/insole via stitching. These are all methods commonly used in mass manufactured shoes so these could be applied to streamline the making process of this shoe!

and that's my brief explanation of rot! a biodegradable shoe project that will entirely cease to exist within fifty years post the end of their life. far less when compared to most modern shoes that can take around two hundred years to degrade depending on materials (and yes those materials likely contain toxins too). There is far more information about this project but I didn't want to completely bombard you with paragraphs of information haha. attached below is some images that better explain some of the things talked about above, as well as my entire capstone presentation with more specific information.

thanks for reading!

-p